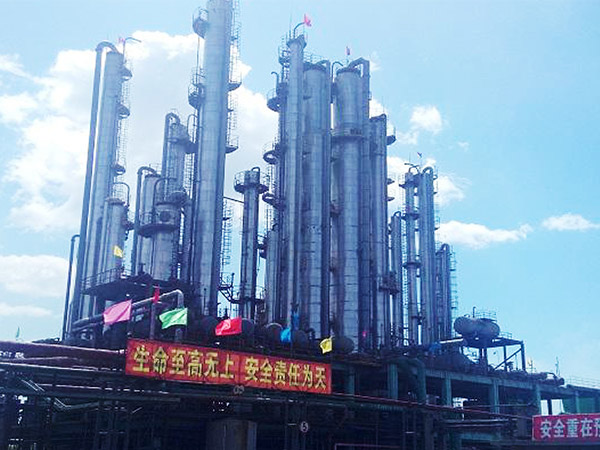

By strengthening the transmission, heat transfer and mass transfer in the chemical process, the equipment size of the chemical process is greatly reduced, the process flow is simplified, the number of devices is reduced, the unit energy consumption, waste and by-products are significantly reduced, and the purpose of energy saving and consumption reduction in the chemical process is achieved. Our company has rich design experience and industrialization performance, and has successful cases in many large-scale chemical enterprises in China.

As an energy recovery system, the heat exchange network is widely used in oil refining, chemical, metallurgy, pharmaceutical and other enterprises, and plays an important role in reducing energy consumption and improving energy utilization rate of enterprises. However, the energy efficiency of the distillation separation process is only 5%. Therefore, it is of great practical significance to use thermal integration technology to reduce the energy consumption of distillation and reaction distillation systems, and has produced good economic benefits for enterprises.

Reactive distillation organically couples the chemical reaction and the distillation process, which can promote the reaction and separation each other, which can not only significantly improve the reaction conversion rate, but also effectively improve the separation ability. The application of reactive distillation technology not only significantly improves the reaction conversion rate, but also reduces the separation load and energy consumption of subsequent products, and even avoids the complex and energy-consuming azeotropic separation process, and achieves significant economic benefits.

By using the difference of Hanson's solubility constant between adsorbent materials and impurities and the principle of pore molecular identification, the specific selective capture of organic impurities with similar properties can be realized, and the purity of chemicals can be increased from 99.60% to 99.99%-99.999%, and the technical indicators are at the leading level in China.

Based on the high-efficiency double-layer impregnated wire mesh filler, the thermal coupling integration technology and the system closed-cascade precision distillation purification technology are developed, which are applied to the purification process of high-purity electronic-grade chemicals, which saves more than 40% energy compared with the traditional technology, and solves the contradiction between multi-stage distillation and energy consumption.

After years of research and development, it now has high-purity solvents for lithium battery electrolytes, including dimethyl carbonate, methyl ethyl carbonate, diethyl carbonate, ethylene carbonate, propylene carbonate, as well as high-purity electronic grade isopropanol, NMP and other solvent refining and purification technologies, successfully realizing the industrial application of 10,000 tons, breaking the long-term monopoly of foreign technology and breaking through the bottleneck of ultra-high purity chemical production technology.

Organic Solvent Recovery Unit:

The organic solvent recovery unit is a device used to recover the waste gas of organic solvents emitted during industrial production, enabling the recycling of resources and reducing environmental pollution. This device technology has advantages such as low energy consumption, high recovery efficiency, and low equipment investment.

As an emerging environmentally friendly solvent, carbonate can widely replace traditional solvents that are toxic and harmful to the environment and humans. It is the main component of lithium - battery electrolytes and is of indispensable value to the development of industries such as new energy vehicles, energy storage, and electronic information.

Extractive Distillation for Crude Benzene Refining Project: A Brief Introduction

The extractive distillation for crude benzene refining project aims to enhance the quality of crude benzene and meet the industrial demand for high - purity benzene - based products. The project uses crude benzene as raw material, which contains various components such as benzene, toluene, xylene, and also impurities like thiophene. Through the extractive distillation technology, with the help of specific extractants, the relative volatility between benzene - based substances and impurities is increased, enabling efficient separation.

In the process, the crude benzene first enters the extractive distillation column, where it comes into full contact with the extractant. Inside the column, the azeotrope formed by the benzene - based substances and the extractant is vaporized from the top of the column, while the impurities are discharged from the bottom of the column along with the extractant. The azeotrope vaporized from the top of the column enters subsequent separation processes. Through operations such as distillation, the extractant is separated from the benzene - based substances. The extractant can be recycled, and the benzene - based substances are further refined to obtain high - purity benzene, toluene, xylene and other products.

This project has significant advantages. Economically, it can produce high - value - added benzene - based products, meeting the needs of industries such as chemical engineering, pharmaceuticals, and electronics, and generating considerable profits for enterprises. In terms of environmental benefits, it reduces the pollution to the environment caused by the emission of impurities in crude benzene, and the recycling of the extractant improves the resource utilization rate. Technically, the extractive distillation technology is mature, with good separation effects and low energy consumption, ensuring the efficient and stable operation of the project.

Structured packing projects are mainly applied in mass transfer and separation processes such as distillation, absorption, and desorption in industries like chemical engineering, petrochemicals, and natural gas processing. The aim is to enhance mass transfer efficiency, reduce energy consumption, and optimize equipment performance.

In the distillation process, structured packing provides a large and uniform mass transfer area for the gas - liquid two - phase. Its unique structure allows the liquid to be evenly distributed on the surface of the packing and form a stable liquid film. The gas then passes through the voids of the packing and comes into full contact with the liquid film. For example, in the crude oil distillation tower of oil refining, structured packing can more precisely separate hydrocarbon components with different boiling points. Compared with traditional packing, it can produce higher - purity products such as gasoline and diesel, while reducing the height of the tower and the reflux ratio, thus lowering energy consumption.

In the absorption and desorption processes, structured packing also plays a crucial role. Taking natural gas purification as an example, in the absorption tower, natural gas containing impurities (such as hydrogen sulfide, carbon dioxide, etc.) comes into full contact with the absorbent on the surface of the structured packing. The impurities are absorbed by the absorbent, achieving gas purification. In the desorption tower, the absorbent rich in impurities releases the absorbed impurities through its interaction with the structured packing, enabling the regeneration and recycling of the absorbent. This not only improves the efficiency of absorption and desorption but also reduces the consumption of the absorbent, cutting down production costs.

In addition, in some fine - chemical production, structured packing projects can meet the strict requirements for high - purity products. For instance, the use of structured packing in the distillation tower of the pharmaceutical industry can more effectively separate high - purity pharmaceutical intermediates, improving product quality and production efficiency and ensuring the safety and effectiveness of drugs.

The methanol comprehensive utilization project is a comprehensive project that uses methanol as the core raw material. Through a series of advanced technologies and processes, it achieves the high - value - added conversion of methanol and produces a variety of chemical products. This project makes full use of the rich chemical properties of methanol, aiming to extend the methanol industry chain, improve resource utilization efficiency, and create significant economic and social benefits.

Project Background:As a basic organic chemical raw material, methanol has a wide range of sources and can be prepared from various raw materials such as coal, natural gas, and biomass. With the adjustment of the global energy structure and the development of the chemical industry, the production capacity of methanol is constantly increasing. Therefore, the comprehensive utilization of methanol and the development of its downstream high - value - added products have become an important direction for the development of the industry.

Main Products and Processes

Olefin Products:The methanol - to - olefins (MTO/MTP) technology is adopted to convert methanol into important olefin products such as ethylene and propylene. These olefins are the basic raw materials for synthesizing numerous chemical products such as plastics, rubbers, and fibers. In the MTO process, methanol is converted into ethylene and propylene through a complex reaction process under the action of a specific catalyst. The reaction conditions are mild, and the product yield is high.

Formaldehyde and Downstream Products:Formaldehyde is produced by the oxidation of methanol, and formaldehyde can be further processed to produce urea - formaldehyde resin, phenolic resin, etc. Urea - formaldehyde resin is widely used in the wood processing industry as an adhesive, while phenolic resin has characteristics such as high - temperature resistance and high strength and is used to manufacture insulating materials, friction materials, etc.

Acetic Acid:Acetic acid is produced by the reaction of methanol with carbon monoxide. Acetic acid is an important organic chemical raw material and is widely used in the food, pharmaceutical, chemical and other fields. This process uses advanced carbonylation technology, with high reaction selectivity and good product quality.

Project Advantages

Significant Economic Benefits:By producing a variety of high - value - added chemical products, the utilization value of methanol is increased, bringing considerable profits to enterprises. At the same time, the implementation of the project can also drive the development of upstream and downstream related industries, creating more economic growth points.

Comprehensive Resource Utilization:It realizes the in - depth development and comprehensive utilization of methanol resources, improves resource utilization efficiency, and reduces resource waste.

Advanced and Reliable Technology:The adopted process technologies have been verified by industrial practice and are characterized by maturity, stability, and high efficiency, ensuring the long - term stable operation of the project.

Environmental Impact and Countermeasures:During the production process, the project will generate certain waste gas, waste water, and waste residue. To reduce the impact on the environment, the project is equipped with advanced environmental protection facilities. The waste gas is treated by desulfurization, denitration, dust removal, etc. and discharged up to the standard. The waste water goes through processes such as biochemical treatment and advanced purification to achieve up - to - standard discharge or recycling. The waste residue is classified and treated, with some being recyclable and the non - recyclable being landfilled safely.

The packing and internals project for the wet decomposition unit of trona is a key supporting project for the wet decomposition process in trona processing. It aims to optimize the performance of the wet decomposition unit and improve the processing efficiency and product quality of trona.

I. Project Background

Trona, as an important chemical raw material, is widely used in various fields such as glass manufacturing, chemical production, and food processing. Wet decomposition is a crucial process in trona processing. Under specific conditions, trona reacts chemically with water and other reaction media to convert its effective components into a form that is easier to be processed in subsequent steps. The packing and internals, as the core components of the wet decomposition unit, directly affect the mass and heat transfer efficiency of the wet decomposition process and the overall operation effect of the unit.

II. Project Content

Packing: The project selects structured packings with high specific surface area, good liquid distribution performance, and low pressure drop characteristics. These packings can provide sufficient contact area for the gas - liquid two - phase, allowing the reaction media to mix and react fully on the surface of the packing, and strengthening the mass transfer process. For example, high - efficiency metal wire - mesh structured packings are used. Their special structural design can make the liquid spread evenly on the surface of the packing to form a stable liquid film, and the gas can pass through the packing layer smoothly and come into full contact with the liquid film, effectively improving the reaction efficiency of trona wet decomposition.

Internals: A variety of internals, including liquid distributors, gas distributors, redistributors, demisters, etc., are carefully designed and manufactured. The liquid distributor can ensure that the reaction liquid is evenly distributed on the packing layer, avoiding liquid maldistribution and ensuring the full utilization of the packing surface. The gas distributor makes the gas enter the tower evenly and achieve good counter - current contact with the liquid. The redistributor is used to collect and redistribute the liquid to prevent the liquid from gathering near the tower wall and ensure the consistent mass transfer effect of the entire packing layer. The demister can effectively remove the liquid droplets carried by the gas at the top of the tower, reducing product loss and the corrosion of subsequent equipment.

III. Project Advantages

Improve production efficiency: High - quality packing and internals can significantly enhance the mass and heat transfer efficiency of the wet decomposition unit, accelerate the decomposition rate of trona, thus improving the production capacity of the unit and reducing production costs.

Enhance product quality: The optimized internal structure of the tower enables more thorough and uniform reactions, reducing the impurity content in the product and improving the purity and quality stability of trona - processed products.

Reduce energy consumption: The rational design of the packing and internals effectively reduces the pressure drop of the unit, reduces power consumption, achieves the goal of energy conservation and consumption reduction, and meets the requirements of sustainable development.

Prolong the service life of the unit: Internals such as demisters can reduce the erosion of corrosive liquid droplets on the equipment. In addition, the reasonable structural design reduces the overall load of the equipment, which helps to extend the service life of the wet decomposition unit and reduce equipment maintenance costs.

IV. Project Implementation and Application

The project team will carry out personalized design and customization according to the scale and process requirements of different trona wet decomposition units. During the project implementation process, relevant standards and specifications are strictly followed to ensure the manufacturing quality and installation accuracy of the packing and internals. At present, this project has been applied in multiple trona processing enterprises, with good operation results, bringing significant economic and social benefits to the enterprises.

The company is a design and production team composed of a number of doctors, masters and engineers, and has its own proprietary technology and rich production experience in the fields of distillation, reaction rectification, crystallization, extraction, adsorption, etc., which are widely used in petrochemical, fine chemical, new materials, new energy, environmental protection, medicine, food and other fields, and have achieved remarkable results.

The company is a design and production team composed of a number of doctors, masters and engineers, and has its own proprietary technology and rich production experience in the fields of distillation, reaction rectification, crystallization, extraction, adsorption, etc., which are widely used in petrochemical, fine chemical, new materials, new energy, environmental protection, medicine, food and other fields, and have achieved remarkable results.